Learn About Montebello Container’s Latest Technology Upgrade

2017 Fibre Box Association Perfect Plant Award

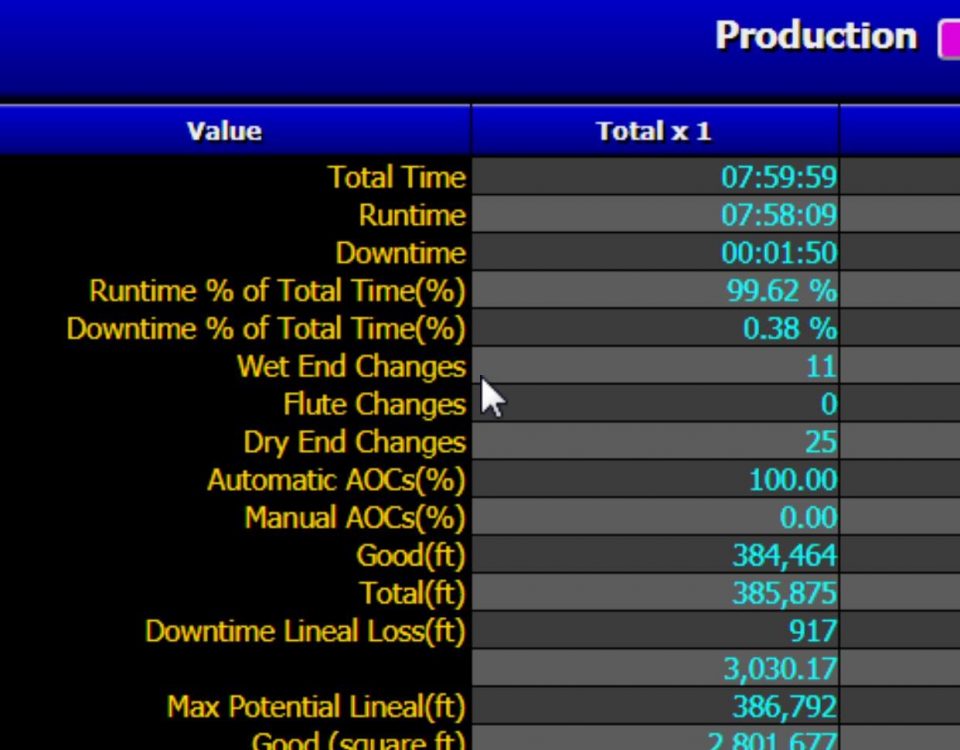

June 25, 2018The Fosber 98″ corrugator has been upgraded and updated to current operating technology;

At the wet end of the corrugator, Montebello Container has updated their Smart singlefacers by installing new glue units, low-level adhesive alarms, updated the glue dam systems and have installed pressure roll upgrades to current run technology along with the upgrading and synchronization of the Fosber Syncro automatic control system. Montebello Container has also added the Thermostack triple preheaters which are now integrated into their automated control system for better warp control.

At the dry end of the corrugator, they installed a Fosber gapless continuous run system at the shear which can order change at 800 feet per minute without severing the web. This is accompanied by the twin 400 robotic slitter-scorer. The robotic system allows for increased score accuracy. The slitter plunges from the double face side up when cutting, which in turn allows for a cleaner print surface to the edge of the sheet. The slitter has no oil for sharpening of the blades, which eliminates board contamination. The Master 400 cut off knife comes with serrated blades for reduced dust at the cutoff. The down stackers are equipped with early discharge capability to reduce cycle time and improved stack quality. This is all supported by an automated mass conveyor system by C & M along with two 4 head unitizers by Signoed and an Opisgal sheet counter.

For questions about Montebello Container facilities or capabilities, please contact our team today! The team at Montebello Container would be happy to answer questions and further discuss capabilities at each of the company’s facilities. To learn more, contact us today!